TELECENTRIC LENSES

Constant Magnification

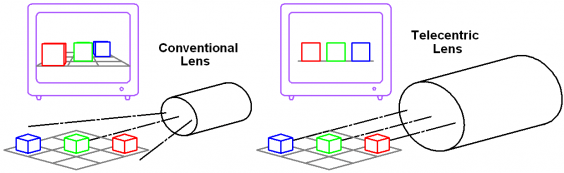

Everyday experience teaches that conventional lenses see an object as being larger if it is close and smaller if it's far. This is part of how we judge distance by eye.

For gauging applications, however, this property can introduce significant errors. For example, bottles on conveyors can "walk" side to side between the rails, thus changing their distance to the camera that's viewing them.

The difference might seem small, but when trying to measure objects to within a few thousandth of an inch, the difference can be critical.

Good telecentric lenses overcome this problem by providing large Magnification Depth of Field (MagDOF). How far an object can change its distance and still appear to be the same size is called magnification depth of field. This is different from image sharpness depth of field, which is the commonly understood meaning of "depth of field."

Large MagDOF means that telecentric lenses are ideal for a great variety of dimensional-gauging applications. Some typical examples include threaded fasteners, machined parts, bottle geometry, and PCB component placement, or any time you want to measure something with little or no perspective error, or with varying distance.

What makes a "good" telecentric lens? Like most things, this depends on the situation. Generally speaking, telecentric optics are divided into three categories: Object space telecentric, image space telecentric, and bi-telecetric lenses or double-telecentric lenses.

For various reasons, telecentric optics of the bi-telecentric lens design offer the greatest MagDOF, and therefore are often the best choice for high-accuracy inspection needs. Light Works' line of Super-EyeTM bi-telecentric lenses offer exactly this high-accuracy capability.

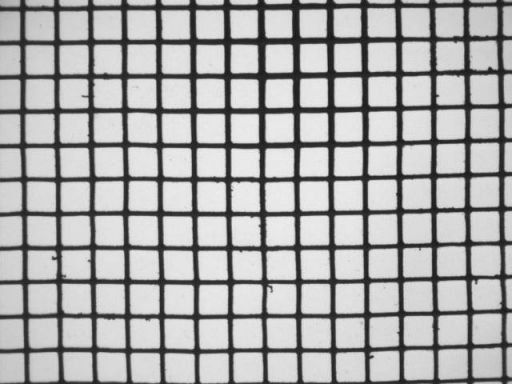

Sometimes you just want your camera to view everything in the field of view from the same angle. The goal isn't necessarily high-accuracy measurement, but constant perspective for other reasons.Take the example image above. This is a view of a ceramic catalytic convertor core using one of our telecentric lenses. That's not a wire mesh, each cell is 6" inches deep!

A conventional lens would only be able see clearly down a few cells at the center of the field of view. The required inspection for cell blockage would be hopeless. A telecentric lens, however, makes the job a snap.

Light Works is an optical engineering company that specializes in telecentric and hypercentric lenses, as well as optical view splitters, and optical engineering consulting. If you have a difficult inspection application, contact us and we'll do our best to help!

Frequently Asked Questions

1. What are telecentric lenses, and how do they differ from standard lenses?

Telecentric lenses are designed to allow a) Only rays of light that are essentially parallel to the optical axis to enter it or b) only rays of light that are essentially parallel to the optical axis to leave it toward the image plane or c) Both of the above.

2. What are the advantages of using telecentric optics in industrial applications?

Telecentric lenses or telecentric optics are often excellent choices for gauging applications where high measurement accuracy is required. In addition, telecentric lenses can provide much greater constancy of measurement even when the object being measured moves closer or farther from the telecentric lens.

3. In which industries are telecentric lenses most commonly used?

Telecentric lenses are typically used in industries where a high degree of measurement accuracy is required. These industries include automotive, fasteners, most machining operations, coining and forming, stamping, grinding, etc. In essence, any industry that produces parts whose dimensions must be accurately maintained might benefit from the use of telecentric optics.

4. How do telecentric lenses improve measurement accuracy?

Telecentric lenses improve accuracy by acting as very long-jawed calipers. What this means is that even if the object being measured moves around in the field of view, it's still measured the same way by a telecentric lens. This includes moving farther or closer to the telcentric lens. This is unlike conventional lenses, including your own eyes, where the object looks smaller if it moves farther away

5. What is the difference between object-space and image-space telecentric lenses?

Object-space telecentric lenses allow only mostly parallel light rays to enter the lens (from the object!) in the first place. This is the way most industrial telecentric lenses operate. Image-space telecentric lenses allow only mostly parallel rays of light to leave the lens and then produce an image. This type of telecentric lens is only used in some very specialized applications that typically are not seen in manufacturing settings.

BUT, telecentric lenses that have both properties, object-space AND image-space telecentricity are called bi-telecentric or double-telecentric. As it turns out, these types of telecentric lens designs offer the best possible constancy of magnification and thus the highest accuracy of measurement. Light Works Super-EyeTM telecentric lenses are of this bi-telecentric design.

6. Can telecentric lenses be customized for specific applications?

Light Works telecentric lenses absolutely can be customized for specific applications. In fact, almost half our telecentric lens sales are modifications of existing designs, or completely new custom designs made specifically for our customer applications.